Chain Lubrication - Penetration is the Key to Success

by Jeremiah "JB" Bacon, S.T.L.E. CLS

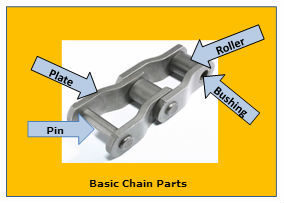

The primary cause of premature chain failure is wear of the internal surfaces of the pins, bushings, plates and rollers. Wear of these critical parts can appear as chain breakage or excessive “stretch”.

When I see chains lubricated with grease or heavy “open gear” type lubricants, it makes me cringe. Greases and very heavy lubricants applied to chains can keep the sprocket protected against wear and the outside surfaces protected against corrosion, but these products do not provide the necessary penetration required to properly lubricate the internal surfaces of the pins, bushings, plates and rollers of each link. Also, these products attract dirt and dust that can accelerate wear rates.

Most chains can be lubricated well with lighter oils ranging from very light penetrating oils up to ISO Viscosity Grade 220 oils for more heavily loaded chains. There are many application methods available including hand oiling and aerosol sprays. Automatic systems are employed when manual lubrication is impractical or dangerous. These methods range from bottle drip or brush oilers to oil baths and more complex automatic spray systems.

Most chains can be lubricated well with lighter oils ranging from very light penetrating oils up to ISO Viscosity Grade 220 oils for more heavily loaded chains. There are many application methods available including hand oiling and aerosol sprays. Automatic systems are employed when manual lubrication is impractical or dangerous. These methods range from bottle drip or brush oilers to oil baths and more complex automatic spray systems.

When selecting a chain lubricant, assess the operating environment as well as the load requirements. Chains that operate at extreme temperatures require special considerations. Extremely low temperatures are best lubricated by very light viscosity synthetic lubricants to ensure flow and penetration into the internal parts at operating temperature. Extreme hot temperatures can use special synthetic lubricants with very high flash points like Polyol Esters or solid film lubricants like graphite, molybdenum disulfide or PTFE (Teflon) suspended in a low flash point, penetrating carrier fluid like a petroleum solvent. These carrier fluids are designed to vaporize, leaving the solid lubricant in place to provide lubrication. Wet environments are best overcome by more frequent application of the lubricant. Important additives for chain lubricants include water displacing rust preventives and antiwear and/or extreme pressure additives.

So remember, when considering chain lubricants remember that penetration is the key to success.